Wire rod is rolled steel primarily of a circular cross section with a diameter of 4-16 mm in coils or bundles. Such products are made of steel, aluminium, copper and non-ferrous alloys. Steel wire rod is used as feedstock for the drawing of wire intended for different applications, as well as in the manufacture of screws, bolts, nails, mesh and reinforcing elements of reinforced concrete products.

Application

Downloads

-

Technical pamphlets

-

SAE 1006 and SAE 1008 wire rod for hot dip galvanizinglearn more

-

-

Catalogue

-

Long productslearn more

-

Steel wire rod production

Wire rod is mainly produced at continuous wire rod hot-rolling mills. Squares with a cross section from 100×100 mm to 200×200 mm and a length of 6-12 m (concast squares produced at continuous casting machines, as well as hot-rolled squares produced at blooming mills or heavy section mills) are used as feedstock.

Prior to rolling, steel billets are subject to heating in reheating furnaces with walking hearth, walking beams or the combined reheating systems under conditions that help to achieve minimum scaling and decarburisation of metal. At the exit of the reheating furnace, billets are subject to hydraulic descaling to remove scale from their surface.

A wire rod mill is usually a single-strand or two-strand facility consisting of a roughing train, intermediate continuous train, finishing train and cooling lines, as well as bundling, handling and finishing end. The number of mill stands in operation depends on the cross section of the billet and the final size.

The finished product section is achieved by subsequent reduction of the billet as it passes the stands complete with rolls of different gauges. The wire rod structure and properties after hot working are achieved in line at the two-stage controlled cooling units. Steel wire rod is water cooled in the first stage and air cooled in the second stage. The wire rod cooling parameters can change within a wide range depending on application, steel grades, dimensions, etc.

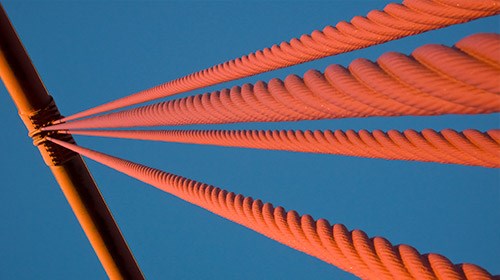

The rolled and cooled wire rod is then fed to a laying head (pipe) for coiling or bundling. Wire rod coils are grabbed by the chain conveyor hook and conveyed to the inspection area, where they are inspected, defected ends are removed and test samples are taken. The finished wire rod coil is repressed and bound by wire rod or strapping bands.

Steel wire rod classification and properties

Steel wire rod is produced in accordance with the requirements set forth in international standards, national standards, industry-specific standards, original manufacturer's standards and regulations, and customer specifications. Steel used for wire rod production is classified in low-carbon, medium-carbon and high-carbon grades when it comes to carbon content and in non-alloy, low-alloy and alloy steel grades when it comes to the quantity of alloys. Standards define the chemical composition and properties for specific applications such as wire drawing, cold working, welded wire manufacturing, etc.

The key standards defining specifications for steel wire rod include: the European standard EN 16120 (in four parts); US standard ASTM A510/A510M; Ukrainian standards DSTU 2770, DSTU 2651, DSTU 4738, DSTU 3684, TU U 27.1-00190319-1280 and TU U 27.1-00190319-1314; and the CIS standards GOST 30136, GOST 380, GOST 2590, GOST 1050 and GOST 14959.

Chemical composition of wire rod used to produce wire in accordance with DIN EN ISO 16120-2:

|

Steel grade |

Weight % of chemical elements |

||||||||

|

C |

Mn |

Si |

S |

P |

Cr |

Ni |

Cu |

N |

|

|

C32D |

0,30-0,35 |

0,50-0,80 |

0,10-0,30 |

max 0,030 |

max 0,030 |

max 0,15 |

max 0,15 |

max 0,25 |

max 0,10 |

|

C38D |

0,35-0,40 |

0,50-0,80 |

|||||||

|

C42D |

0,40-0,45 |

0,50-0,80 |

|||||||

|

C48D |

0,45-0,50 |

0,50-0,80 |

|||||||

|

C50D |

0,48-0,53 |

0,50-0,80 |

|||||||

|

C52D |

0,50-0,55 |

0,50-0,80 |

|||||||

|

C56D |

0,53-0,58 |

0,50-0,80 |

|||||||

|

C58D |

0,55-0,60 |

0,50-0,80 |

|||||||

|

C60D |

0,58-0,63 |

0,50-0,80 |

|||||||

|

C62D |

0,60-0,65 |

0,50-0,80 |

|||||||

|

C66D |

0,63-0,68 |

0,50-0,80 |

|||||||

|

C68D |

0,65-0,70 |

0,50-0,80 |

|||||||

|

C70D |

0,68-0,73 |

0,50-0,80 |

|||||||

|

C72D |

0,70-0,75 |

0,50-0,80 |

|||||||

|

C76D |

0,73-0,78 |

0,50-0,80 |

|||||||

|

C78D |

0,75-0,80 |

0,50-0,80 |

|||||||

|

C80D |

0,78-0,83 |

0,50-0,80 |

|||||||

|

C82D |

0,80-0,85 |

0,50-0,80 |

|||||||

|

C86D |

0,83-0,88 |

0,50-0,80 |

|||||||

|

C88D |

0,85-0,90 |

0,50-0,80 |

|||||||

|

С92D |

0,90-0,95 |

0,50-0,80 |

|||||||

Chemical composition of some carbon steel grades used to produce wire rod for wire drawing as per ASTM A510M:

|

Steel grade |

Weight % of chemical elements |

||||||||

|

C |

Mn |

Si |

S |

P |

Cr |

Ni |

Cu |

N |

|

|

SAE 1006 |

max 0,08 |

0,25-0,40 |

With the agreement of the customer |

max 0,05

|

max 0,04

|

max 0,15

|

max 0,15

|

max 0,3

|

max 0,10

|

|

SAE 1008 |

max 0,10 |

0,30-0,50 |

|||||||

|

SAE 1010 |

0,08-0,13 |

0,30-0,60 |

|||||||

|

SAE 1012 |

0,10-0,15 |

0,30-0,60 |

|||||||

|

SAE 1013 |

0,11-0,16 |

0,50-0,80 |

|||||||

|

SAE 1015 |

0,13-0,18 |

0,30-0,60 |

|||||||

|

SAE 1016 |

0,13-0,18 |

0,60-0,90 |

|||||||

|

SAE 1017 |

0,15-0,20 |

0,30-0,60 |

|||||||

|

SAE 1018 |

0,15-0,20 |

0,60-0,90 |

|||||||

|

SAE 1019 |

0,15-0,20 |

0,70-0,10 |

|||||||

|

SAE 1020 |

0,18-0,23 |

0,30-0,60 |

|||||||

|

SAE 1021 |

0,18-0,23 |

0,60-0,90 |

|||||||

|

SAE 1022 |

0,18-0,23 |

0,70-1,0 |

|||||||

|

SAE 1023 |

0,20-0,25 |

0,30-0,60 |

|||||||

Chemical composition and mechanical properties of wire rod intended for wire drawing in accordance with DSTU 2770 / GOST 30136:

|

Steel grade |

Weight % of chemical elements |

Max ultimate tensile strength, Н/мм²(кгс/мм²), max |

Min RoA, %, min |

||||||||

|

C |

Mn |

Si |

S |

P |

Cr |

Ni |

Cu |

N |

|||

|

Ст0М |

max 0,12 |

- |

- |

max 0,05 |

max 0,04 |

max 0,03 |

max 0,03 |

max 0,03 |

max 0,10 |

470 (48) |

66 |

|

Ст1кп |

0,06-0,12 |

0,25-0,50 |

max 0,05 |

470 (48) |

66 |

||||||

|

Ст1пс |

0,06-0,12 |

0,25-0,50 |

0,05-0,15 |

470 (48) |

66 |

||||||

|

Ст1сп |

0,06-0,12 |

0,25-0,50 |

0,15-0,30 |

470 (48) |

66 |

||||||

|

Ст2кп |

0,09-0,15 |

0,25-0,50 |

max 0,05 |

470 (48) |

60 |

||||||

|

Ст2пс |

0,09-0,15 |

0,25-0,50 |

0,05-0,15 |

470 (48) |

60 |

||||||

|

Ст2сп |

0,09-0,15 |

0,25-0,50 |

0,15-0,30 |

470 (48) |

60 |

||||||

|

Ст3кп |

0,14-0,22 |

0,25-0,50 |

max 0,05 |

540 (55) |

60 |

||||||

|

Ст3пс |

0,14-0,22 |

0,25-0,50 |

0,05-0,15 |

540 (55) |

60 |

||||||

|

Ст3сп |

0,14-0,22 |

0,25-0,50 |

0,15-0,30 |

540 (55) |

60 |

||||||

Chemical composition and mechanical properties of some types of wire rod intended for welded wire manufacturing in accordance with the TU U 27.1-00190319-1280 specification:

|

Steel grade |

Weight % of chemical elements |

Max ultimate tensile strength, Н/мм²(кгс/мм²), max |

Min RoA, %, min |

|||||||||

|

C |

Mn |

Si |

S |

P |

Cr |

Ni |

Cu |

Al |

N |

|||

|

Св-08 |

max 0,10 |

0,35-0,60 |

max 0,03 |

max 0,040 |

max 0,040 |

max 0,15 |

max 0,30 |

max 0,25 |

max 0,01 |

- |

430 (44) |

60 |

|

Св-08А |

max 0,10 |

0,35-0,60 |

max 0,03 |

max 0,030 |

max 0,030 |

max 0,12 |

max 0,25 |

max 0,25 |

max 0,01 |

max 0,010 |

430 (44) |

60 |

|

Св-08ГС |

max 0,10 |

1,40-1,70 |

0,60-0,85 |

max 0,025 |

max 0,030 |

max 0,20 |

max 0,25 |

max 0,25 |

- |

max 0,010 |

640 (70) |

50 |

|

Св-08Г2С |

0,05-0,10 |

1,80-2,10 |

0,70-0,95 |

max 0,025 |

max 0,030 |

max 0,20 |

max 0,25 |

max 0,25 |

- |

max 0,010 |

690 (70) |

48 |

|

Св-08Г1НМА |

max 0,10 |

1,00-1,50 |

0,20-0,45 |

max 0,010 |

max 0,015 |

max 0,25 |

0,50-0,70 |

max 0,25 |

- |

max 0,008 |

850 (87) |

48 |

Steel wire rod application

Steel wire rod is mainly used to manufacture wire and metalware. Size, chemical composition and properties vary depending on the application of the finished products.

Low-carbon wire rod in coils is used for wire drawing, as well as to manufacture metal mesh and metalware. The key requirements for this product are the absence of any wire drawing breakage and surface defects, as well as uniform geometry and mechanical properties.

High-carbon wire rod is used to manufacture ropes, prestressing strands, springs, etc. Such products shall have a uniform fine pearlite structure (achieved by special cooling after rolling), without surface and internal defects that result in high breakage, as well as minimum inconsistency in chemical composition and mechanical properties.

Welding wire rod is used as feedstock to produce welded wire and electrodes. The key requirements include high ductility (achieved by slow cooling at the rolling mill), consistent quality and minimum content of detrimental impurities. Low-carbon, low-alloy and alloy steel grades are used for such products. Cold-heading quality wire rod is used to produce metalware by cold heading. The rolled steel shall be free of any surface damages and wire rod samples shall withstand an upsetting test of at least 2/3.

| Product

|

Application

|

Material used

|

| Wire

|

|

Low-carbon, medium-carbon, high-carbon, low alloy

|

| Cold-worked reinforcement

|

|

Low-carbon and high-carbon

|

| Mesh

|

|

Low-carbon, medium-carbon and alloy steel

|

| Electrodes

|

|

Low-carbon and alloy steel

|

| Fibre

|

|

Low-carbon, medium-carbon and high-carbon steel

|

| Nails

|

|

Low-carbon

|

| Ropes

|

|

Wire rod made of medium-carbon, high-carbon and stainless steel

|

| Fastening (bolts, nuts, screws, self-tapping screws, etc)

|

|

Low-carbon, medium-carbon, high-carbon and alloy steel

|

| Tyre cord

|

|

High-carbon

|

Buying steel wire rod

Metinvest offers a wide size range of wire rod from carbon, low-alloy and alloy steel grades for construction and machine building. Wire rod can be purchased through the Group’s global sales network of 38 sales offices in Europe, Asia, Africa and North America, as well as 16 metal service centres in Ukraine and authorised dealers.

Get in touch

Find the nearest office

Subscribe to our newsletter