Construction progress of hospitals to fight the coronavirus

The epidemic of the COVID-19 coronavirus in China became a real challenge not only for medical workers and scientists but also for construction workers.

They started building the 1,000 bed-Huoshenshan Hospital in Wuhan on 23 January this year, and the first patients arrived there on 3 February. The construction of another hospital, Leishenshan, for 1,600 beds, took only 13 days. Both hospitals were designed according to modular (unit) construction principles, where a metal frame and sandwich panels from galvanised steel played a key role.

The two brand-new hospitals extend the city's capabilities in providing help to people infected with the COVID-19 coronavirus. “What was done within a few days in China is impressive indeed. This is an achievement not only for the healthcare but also for logistics, planning and architecture,” - these are the words of Michael Ryan, Executive Director of the World Health Organisation’s Health Emergency Programme, about the two new hospitals.

Doctors and medical workers from across China were involved in working on the new hospitals.

Photo depositphotos.com

A great size of hospitals

Huoshenshan Hospital takes up about 32,000m2, while the space of Leishenshan Hospital, which was constructed on a parking lot, comprises around 75,000m2. Both buildings include intensive care units, patients wards, consultation rooms, as well as medical examination rooms.

According to the Xinhua news agency, about 7,000 specialists took part in building Huoshenshan Hospital.

Hospital structures: how they were made

Unit construction has become a well-established process with a tried-and-true script. First, excavators and bulldozers levelled the soil on the construction site in about 48 hours. Then 20cm of sand was scattered above the ground. Two layers of geotextile, made from synthetic fibres with a waterproof layer in the middle, were laid on top of the sand layer. Then the sand was scattered again. After that, the construction workers poured the concrete base over several days. Beams were laid on the foundation. A metal frame was installed on the beams. After this, the hospital was "assembled" using the sandwich panels.

Photo source www.wsj.com

The advantages of using steel structures in the construction

Steel structures have proven their efficiency in the construction segment for a long time. They allow combining both the functionality and the architecture and give new opportunities to implement various concepts.

Talking about unit construction, the sandwich panels from hot-rolled galvanised steel and the metal frame provide high-speed construction, cost-effectiveness, functionality, maintenance, flexibility, and recyclability of metal structures. Their installation saves both time and money to a large extent in comparison with a cast concrete frame. Savings start with the foundation when building from steel structures, as the weight of steel buildings are 40-60% lighter than concrete buildings. This means that the foundation can be lighter to transfer required loads, and is also essentially cheaper. Besides, the speed of the construction works themselves is faster than the concrete works.

Photo depositphotos.com

Of course, we should remember about the reliability of such buildings. The whole manufacturing process of both steel-rolled products and finished building steel structures is carried out in a factory, which guarantees continuous quality control and the safety and integrity of structures.

Thanks to these advantages of modular steel construction, Chinese builders managed to build two hospitals in Wuhan in such a short time.

Specific features of wards in modular hospitals

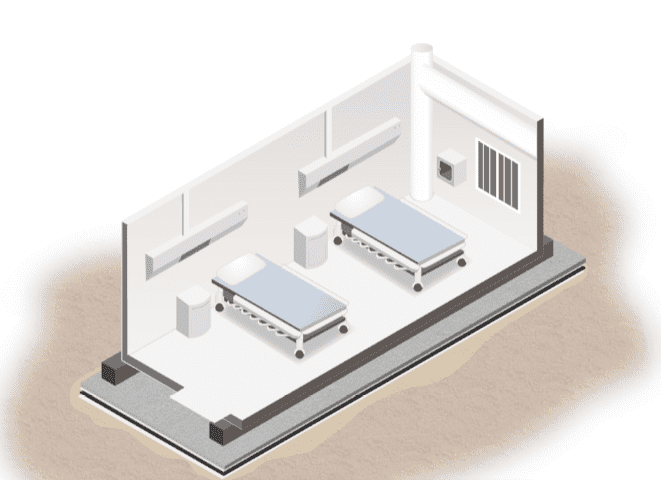

Thanks to their modular structure, hospital wards with spaces larger than 30m2 may have various configurations. One ward can house two patients.

Everything was designed to allow doctors and other medical personnel to fight the coronavirus in an efficient way by minimising the risk of infection. Each ward can be depressurised quickly.

Using metal isolation wards with holes on each side, hospital workers can deliver food to patients without physical contact. Besides, stand-alone probationary wards were built in the hospitals.

Photo depositphotos.com

Modern technologies in Chinese hospitals

To minimise the risk of infection among the personnel, special medical robots, which deliver medicines and carry out diagnoses, are used in the new hospitals. All hospital departments are equipped with special infrared scanners capable of catching the symptoms of employees' infections.

Furthermore, the doctors from the hospitals in Wuhan can consult with other experts using a video system that connects them with a general hospital in Beijing. The installation of this system took less than 12 hours.

It should be noted that the hospitals in Wuhan were designed by the example of a temporary modular hospital, Xiaotangshan, which was built in Beijing in 2003 to fight the epidemic of Severe Acute Respiratory Syndrome (SARS). According to the Chinese press, the construction was completed in seven days. Some 99% of the stricken hospital patients recovered, and none of the medical workers were infected.

We hope that once again dedicated medical personnel will be able to stop the COVID-19 coronavirus from spreading and to cure the thousands of infected people.