Project scope

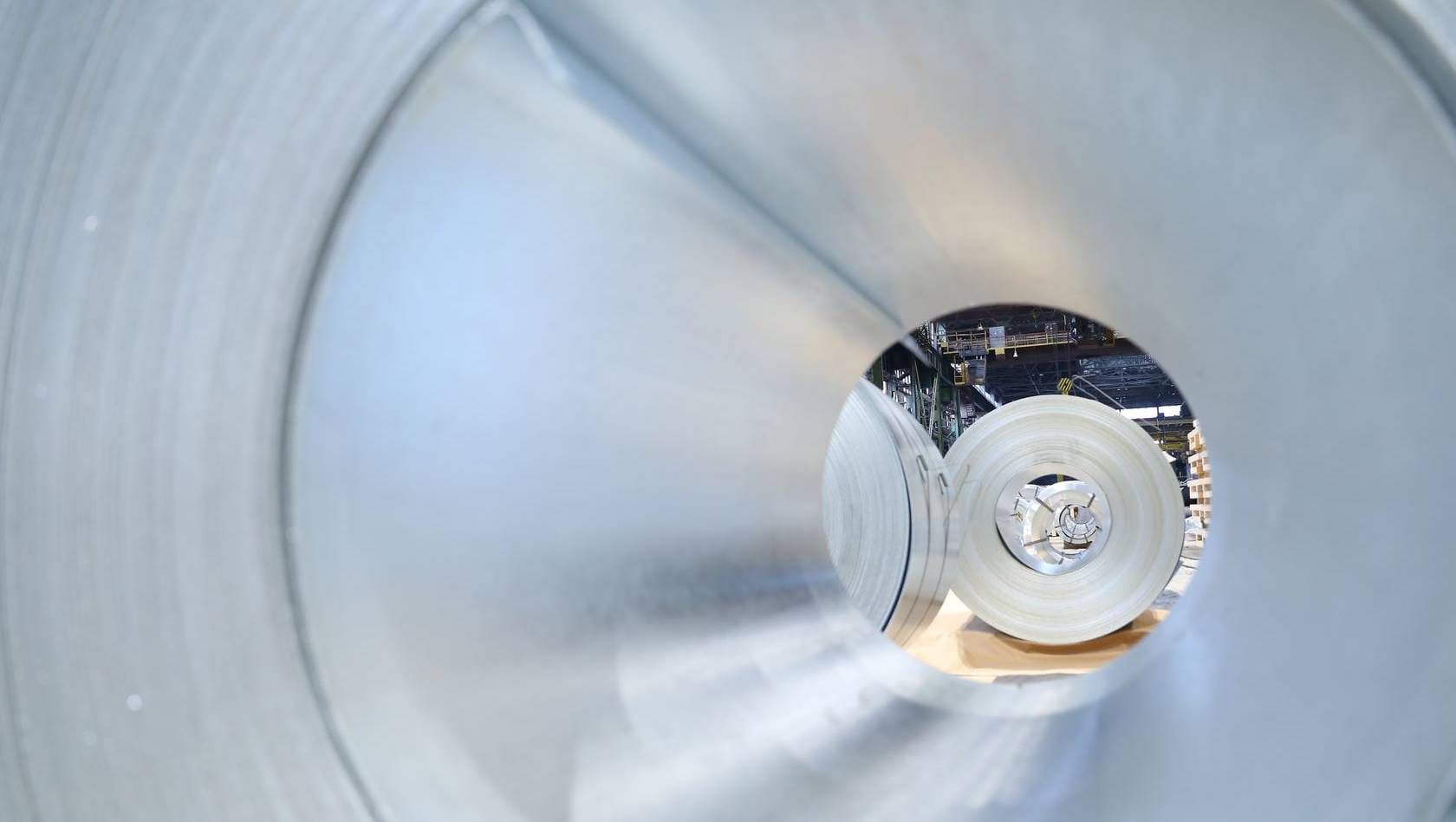

Ilyich Steel plans to construct a cold-rolling shop. It will consist of a continuous cold-rolling mill combined with a pickling line, as well as three state-of-the-art lines for zinc, aluminium zinc and polymer coatings. Project investments will exceed US$800 million for the first phase.

Metinvest will engage a major foreign contractor with experience in similar projects.

In 2025, after the completion of the project’s first phase, the mill will be able to produce around 1.2 million tonnes a year of highly competitive cold-rolled and galvanised steel, as well as polymer-coated steel. The production capacity will include more than 400 thousand tonnes of cold-rolled coils, more than 600 thousand tonnes of galvanised coils and more than 140 thousand tonnes of polymer-coated coils.

The project’s second phase includes building a new annealing furnace department, skin pass mill and coil slitting line, as well as the new galvanised coil coating line.

After the second phase is completed, the annual cold-rolled production capacity will exceed 1.6 million tonnes.

Project impact

The new cold-rolled steel production technology will allow Metinvest to enter the premium galvanised and colour-coated coil product segments. The latter is not currently represented in the Group’s product line. It will also help to improve quality and expand the cold-rolled product range.

The products are intended mainly for the Ukrainian market, where these high-quality locally produced coils will be able to replace low-quality imported ones. The rolled coils will also be exported to countries in the CIS and Europe.

The project has an environmental aspect, as well. The existing sulfuric acid pickling technology will be replaced with hydrochloric acid technology, which uses a regeneration unit to recycle the acid back into production.

The new shop will feature highly efficient gas cleaners that meet the latest Ukrainian and European environmental standards. This equipment will ensure that the emissions of harmful substances remain 1,5-3 times lower than the maximum permissible norms in Ukraine. It will also reduce fuel consumption by 20%.

In addition, the new facility will create more than 230 new jobs.