High-strength rolled products are most suited for circumstances where traditional materials have proven ineffective. Such metal has high impact toughness even at low temperatures, as well as good ductility and weldability.

There are also special advantages that make the use of high-strength rolled products indispensable in the machine building industry.

Less fuel for machines

Environmental standards governing atmospheric emissions are becoming increasingly stringent and serve as an additional incentive for the emergence of new materials in the machine building industry, including high-strength ones.

Most driving mechanisms consume fuel. Machines manufactured from high-strength rolled products are much lighter than those made from traditional steels. Lighter mechanisms need less fuel, which also benefits the environment.

Simple and quick repair

Machines that interact with an abrasive medium wear out over time. While some parts of such equipment can be repaired, others must be completely replaced.

For example, on an excavator bucket, the teeth that bite into the mine rock wear out most often. To repair the teeth, they are either built-up by welding or a new spare part is welded to the bucket.

Previously, the teeth were repaired using the first method: 110G13L grade steel was built-up and the part was hardened in the process of working with a hard surface. A bucket had to be removed and sent to a specialised repair company to be built-up. Nowadays, everything is simpler: a bucket is almost like a set of building blocks. There is no need to send the part anywhere, as all parts can be replaced by the end user. The teeth are now interchangeable parts that are simply welded to the bucket.

The application of high-strength steels in the mining industry extends the service life of high-wear units by more than fivefold, even at low temperatures.

The interchangeability of parts has become the norm for agricultural machinery. Most often, when working with soil, harrows, ploughs and blades wear out. Land cultivation is more effective with lighter parts. When choosing steel parts for equipment, machine builders are guided by a desire to reduce price without sacrificing quality.

Cost-effective welding of parts

The maintainability of modern engineering mechanisms and parts made of high-strength steels is much higher and simpler compared with traditional steel grades.

For example, thin metal requires less welding material. Parts made from lower-carbon steel can be welded using cheaper electrodes.

Thus, stronger steel grades increase the overall efficiency of both manufacturing and operating the final product: machines and mechanisms.

Recognising the advantages of high-strength steel, Metinvest’s mining and enrichment plants use it to repair dump trucks. At Central GOK, mined rock is transported by BelAZ trucks. The truck bodies are lined with metal plate to protect them from abrasion. The loading and unloading of mined rock wear out this plate due to the constant impact of loads and rock movement along the truck body.

The BelAZ truck bodies are lined using Metinvest's high-strength, wear-resistant plate manufactured from 25HGSR steel.

Tests have shown that this increases the lining’s service life by 50% to three years while reducing the dump truck’s lining weight by 20%.

Each part has its own technology

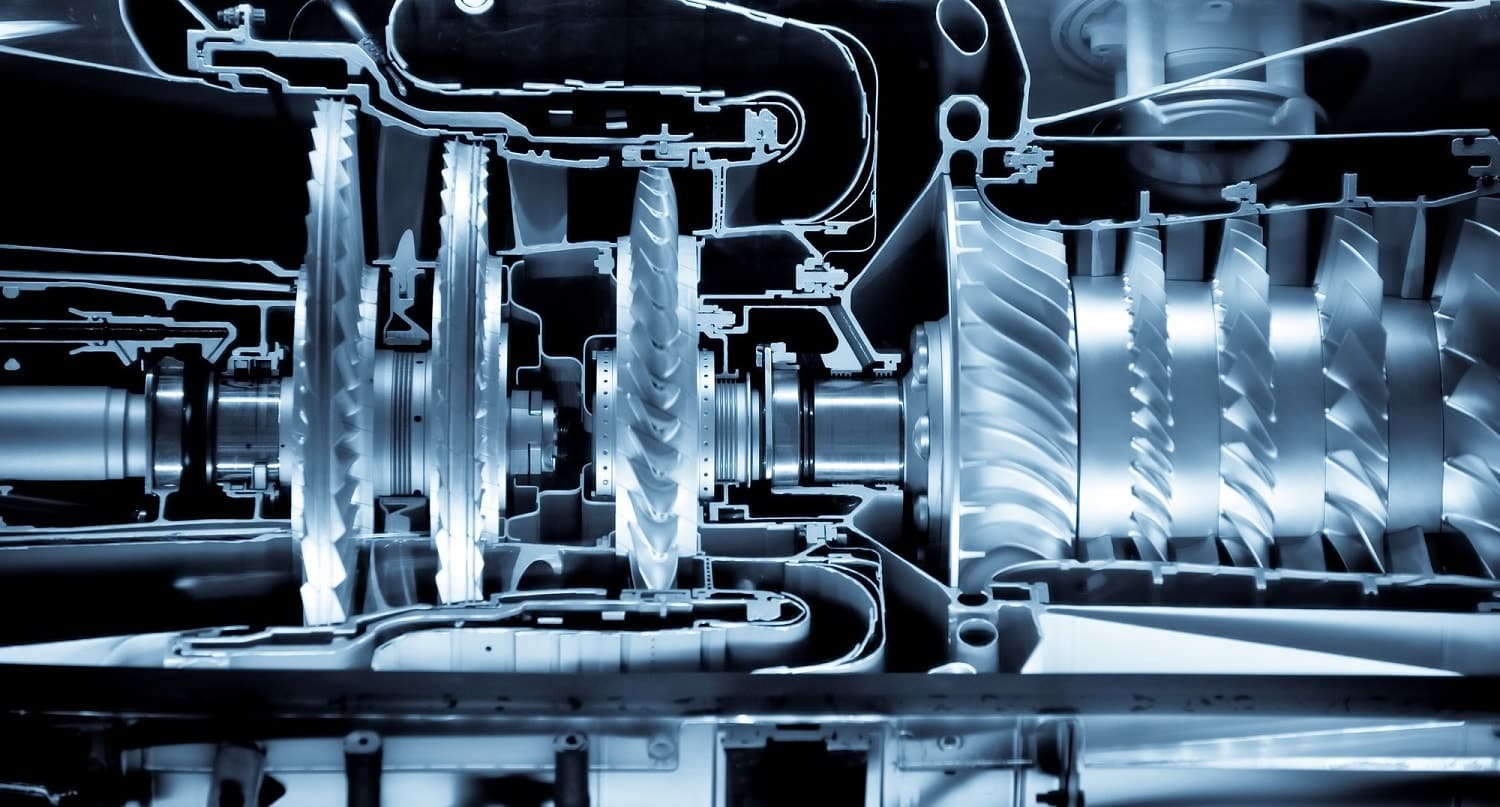

The most popular production technologies used to make high-strength rolled products for the machine building industry are quenching with tempering and thermomechanical rolling.

Each type of machine part requires various metal processing technologies and different steel grades.

Quenching with tempering is mainly used in those cases where a high resistance to abrasive wear is needed. This includes various parts of underground mining equipment, such as conveyor elements that transport mined rock.

Agricultural machinery parts like tractor buckets, harrows, ploughs and chains are also produced from quenched steel.

Thermomechanically hardened steel is used to produce parts that require reduced weight while maintaining or increasing load-bearing capacity and strength without abrasive impact. This includes crane beams, various cabins, casings and car bodies.

Consumers of high-strength rolled products

Metinvest produces heavy plates and coils for the machine building industry. The vast majority of buyers of the Group’s products are service metal centres, which manufacture semi-finished products for machine builders. They cut plates, shape parts, drill holes and do chamfering.

High-strength rolled products are also purchased by machine building companies that have equipment for metal processing.

Another category of consumers is engineering companies that supply integrated solutions for the machine building industry. For example, they might be developing a project for a raw material mining and processing facility. Such companies attract subcontractors for each individual element of the facility and provide a turnkey solution.

Metinvest’s products are in demand among machine builders in Ukraine, as well as countries in the CIS and Europe. Among the Group’s clients are the mining equipment producer Corum Group (Ukraine); shipbuilding companies such as Smart Maritime Group (Ukraine), Vard (Norway), Fincantieri (Italy) and Brodosplit (Croatia); the Ukrainian agricultural equipment manufacturers Elvorti and Veles Agro; and the Polish division of the Finnish group Miilux Oy, which manufactures wear-resistant parts for the machine building industry.