These qualities are drawn mostly from the outstanding properties of the steel the Swiss knives are made of.

Early triumphs of Victorinox steel knives

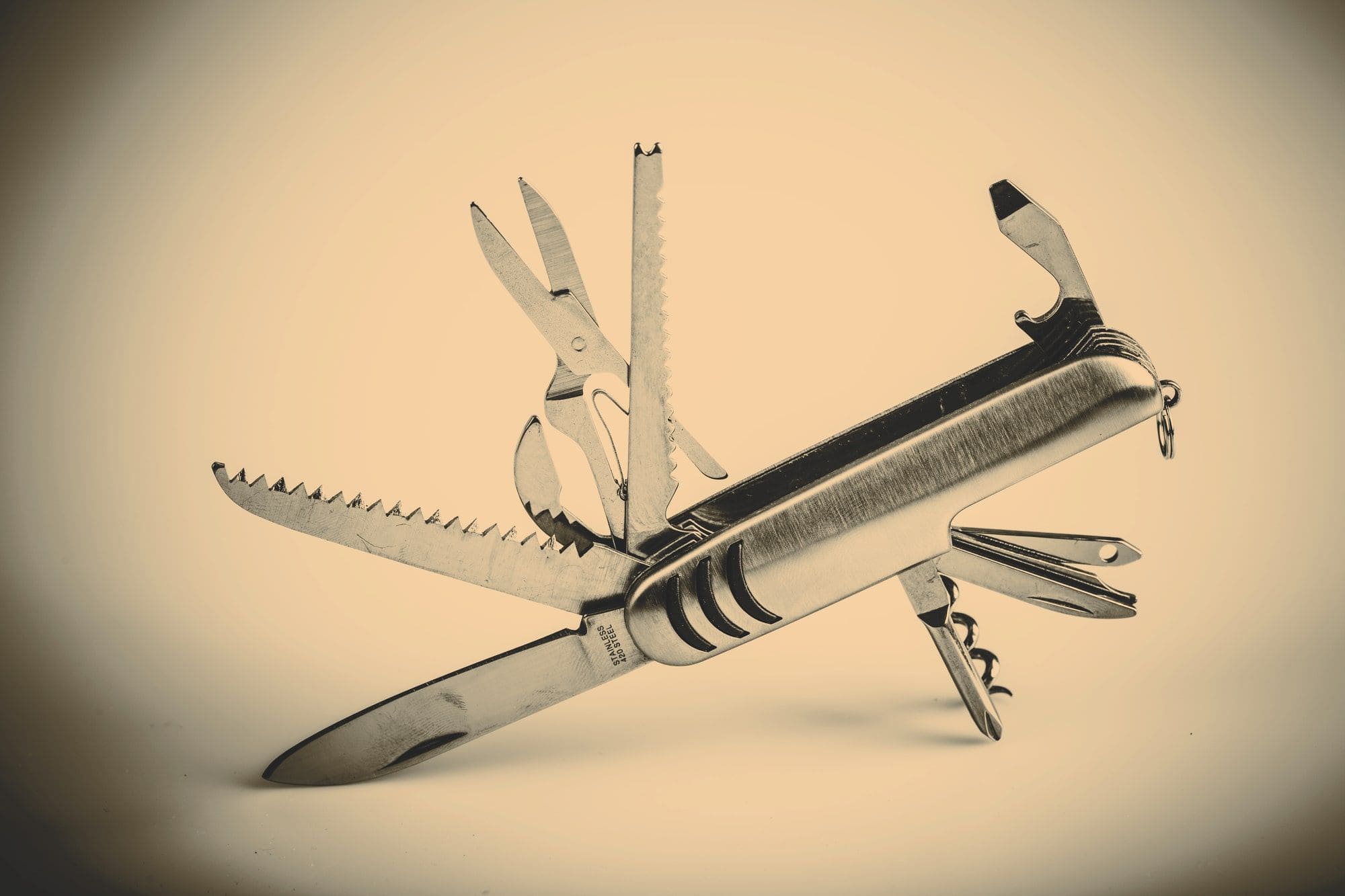

Around a thousand employees are engaged in the production of Swiss knives. Tens of thousands of knives come off the production line each day after passing through hundreds of production stages. Almost all the knives are produced for export. They are used in more than a hundred countries around the world. The product fits its place whether in an officer’s case, next to a shoemaker’s machine, or in the desk of the US president. That said, the multi-functional Victorinox knife became iconic in its country of origin. For over 100 years, the Swiss Army has used this steel tool. The term “Swiss Army knife” has become an established term in Switzerland to mean “practicality” and “multi-functionality”.

The Swiss company Victorinox was founded by Karl Elsener, who was born into a family of haberdashers that owned a shop in Zug (Switzerland) for many generations. However, Karl did not want to become a haberdasher and went away to work as an apprentice in cutler’s workshops in France and Germany, where he learned to make surgery scalpels. Although Elsener refused to continue the family haberdashery business, his mother Victoria actively supported his endeavours.

In 1884, shortly before his twenty-fifth birthday, Karl made his first knife in his own cutler’s workshop located in the small village of Ibach, near Geneva. That is considered the day on which the world-famous Swiss knife manufacturer was founded (called Elsener at that time). Today, Victorinox remains a family-owned company run by Carl Elsener IV.

The year 1891 was the next important milestone in the company’s development, when Karl Elsener I combined 30 Swiss cutlers into the Association of Swiss Master Cutlers, which still exists today. At those times, knives were made manually, and the output of each cutler’s workshop was relatively low. Cutlers needed small lots of expensive metal and other components. The association’s establishment made it possible for Elsener and his peers to save on the raw materials used in knife production. Furthermore, thanks to the consolidation of production capacities, association members received an impressive order to produce knives for Swiss Army soldiers, winning a contract over German knifemakers.

Despite pushing overseas competitors out of the Swiss market, though, Elsener could not withstand the competition from local cutlers. In 1893, the second-largest Swiss cutlery company, Paul Boéchat & Cie (later renamed Wenger SA), won an order to provide knives to the Army. The two companies fought over this client with varying success until Victorinox acquired its long-term rival in 2005.

At the time, the company’s representatives justified the acquisition out of concerns that the assets of Swiss producer Wenger could be acquired by a foreign investor. Victorinox’s representatives thought such a deal could lead to a deterioration in the quality of traditional Swiss products. They stated that Wenger would have carte blanche in marketing, production and sales policy. In 2014, however, the production of knives under the Wenger trademark completely stopped. This made Victorinox the only producer of army knives in Switzerland.

Advances in knife production

Back in the 1890s, the competition was far from over – Karl Elsener and Wenger were fighting fiercely over the contract to produce the Modell 1890 knife. It had a blade, awl, can opener and screwdriver. The knife was used mainly for opening canned food and assembling/disassembling the Swiss M1889 service rifle.

However, Elsener had a special opinion regarding the Modell 1890. In 1897, Karl created and patented the knife design that is known around the world today as the Swiss Army knife. In his design, the tools were attached to the knife handle using a spring mechanism. In addition, Elsener equipped the knife with additional features designed for the target users, namely Swiss Army officers. The knife featured additional tools such as a small cutting blade to erase mistakes in documents and ... a corkscrew.

This innovation was a commercial success. Not only Swiss soldiers but also civilians –students, farmers and workers – wanted to have this officer’s knife. The public interest in this patented model gave rise to various versions of the knife with different tools. Elsener attached a nail file, scissors, tweezers, magnifying glass and so on to the spring – up to 30 tools in total. Today, the Museum of Modern Art in New York exhibits the Champion model, which is considered a pinnacle of industrial design. It features 16 blades and attachments that can perform 29 different functions.

The buying boom at the end of the 19th century significantly improved the financial situation of Elsener’s company. In 1909, Elsener’s darling mother Victoria passed away. Grieving the loss, he changed the name of his company from Elsener to Victoria. That was also when Karl registered the white cross and red shield emblem as a trademark, which is still in use.

Another boom the Elsener family experienced came in 1945, at the end of World War II. The Swiss Army knife gained tremendous popularity among the allied armies. Almost every soldier returning home from the battlefield tried to buy a Victorinox knife as a souvenir.

Steel in Swiss knives

In the early 1920s, the Englishman Michael Faraday and the Frenchman Pierre Berthier invented corrosion-resistant steel. Karl Elsener immediately recognised the unique properties of stainless steel and started using it to make knives. Elsener also decided to eternalise the outstanding invention and renamed his company by adding the word “inox” – the French term for stainless steel – to the company’s name. This is how the Victorinox trademark gained all the attributes for which it is known to consumers today.

His admiration for the new material is not accidental. A knife is formed around the steel from which its blade is made. The steel determines a knife’s longevity and sharpness, the materials that will be used to sharpen it, and so on. Before the invention of stainless steel, rust was a huge problem for knifemakers and owners. Once corrosion appeared, it penetrated further into the blade and could not be stopped. That said, the first productivity losses were observed when the knife’s cutting edge, which was just a fraction of a millimetre in width, started to rust.

In 1931, the oldest Swiss electrical engineering company – Brown, Boveri & Compagnie – received an order from Victorinox to manufacture the world’s first all-electric hardening plant. This innovation ensured the consistently high quality of Victorinox knives.

What are Swiss knives made of today? The company uses Dauphinox steel produced in France by Bonpertuis. These are medium-carbon, high-chromium, corrosion-resistant steels (grades X55CrMo14, X50CrMoV15, X46Cr13 and X38CrMo14, depending on the tool type).

Even today, the production of each blade for the Swiss Army knife starts from flat steel. Before being used in production, each centimetre of steel is inspected at the plant (despite the impeccable reputation of the raw materials producer). The steel’s homogeneity, composition and compliance with specifications are all checked, because any defect results in poorer wear and corrosion resistance. Confidence in the superb steel characteristics allows Victorinox to provide a lifetime guarantee on its products.