In 2020, Metinvest Group’s steel mills launched the production of 54 new products.

Most of the new products were developed last year in the steel plate (25) and hot-rolled coil (14) segments. New products were also developed in the cold-rolled coil (6), galvanised coil (5), semi-finished product (3) and tube (1) categories.

Azovstal took the lead in terms of new products launched, followed by Ilyich Steel with the most diverse mix of new products. Zaporizhstal came in third.

Plates

In the steel plate category, Metinvest's focus last year was the development of products for the shipbuilding industry. Group enterprises began to produce goods according to a new standard: DNV GL 2019. To be able to manufacture rolled steel with special requirements for chemical composition, Metinvest received certification from Det Norske Veritas and Germanischer Lloyd.

The standard sets out more stringent requirements for quality parameters to improve the weldability of steels. As a result, many high-strength grades are rolled at the enterprises using advanced steel production technologies, in particular, thermomechanical rolling. In 2020, 30,000 tonnes of such products were shipped to customers.

Metinvest also began to produce a new steel grade, S500ML, which is a high-strength material for construction and heavy machinery. It is subject to thermomechanical rolling and benefits from better weldability compared to steel grades with similar strength properties but produced using different technologies.

Semi-finished products

Last year, Metinvest began to produce three new types of semi-finished products, two of which (grades DC01 and S220GD) were made to order for Slovak steel company U.S. Steel Košice. Slabs are used for the production of hot-rolled coils, after which one grade is used for the production of cold-rolled coils and another grade for the manufacture of galvanised coils.

Hot-rolled coils

The modernised 1700 HSM at Ilyich Steel began the production of extra-thin material with the thickness range from 1.2 millimetres (mm) to 1.7 mm, according to European standards. Extra thin rolled products are in short supply on the market. Such steel is not a part of mass production, as it significantly reduces the productivity of equipment.

Before the revamp of the hot strip mill, these products were made in small quantities only according to GOSTs and were primarily processed at Metinvest’s own mills.

The products are used for cold rolling and for the substitution of cold-rolled material of same thickness in different applications, including the production of galvanised coils. In particular, thin-gauge steel is used for the fabrication of light, thin-walled steel structures (LTWS), for example, formed sections for construction, sandwich panels and corrugated metal sheets. Last year, Ilyich Steel supplied over 35,000tonnes of such extra thin hot-rolled materials to the domestic and export markets.

Metinvest enterprises also began to supply L360N grade steel in coils, which was not produced in Ukraine before, to tube producer Interpipe. Rolled steel used for tube production meets stringent requirements for chemical composition and mechanical properties.

Several types of formed profiles with new thicknesses (2.5, 3.5, 4.5 and 5.7 mm) were developed at Zaporizhstal to produce steel channels from hot-rolled coils. Around 12,500 tonnes of these products were supplied to the market to meet demand from the construction and heavy machinery industries. Due to lower metal intensity, these profiles are more effective and cost efficient.

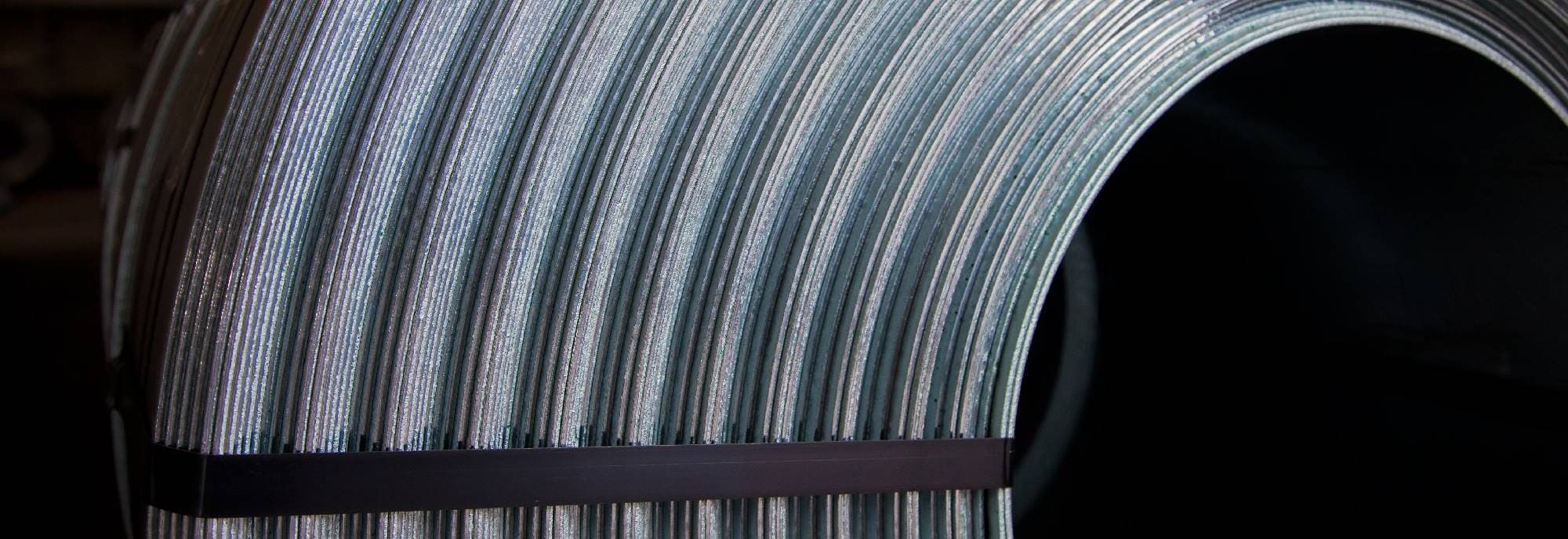

Galvanized coils

Unisteel has developed the production of the S250GD galvanised, high-strength steel grade with a thickness range up to 2 mm and different classes of zinc coatings. The products are used for the manufacturing of light, thin-walled steel structures and load-bearing profiles, which are in demand for the construction of low-rise and commercial buildings, agricultural facilities and solar power plants.

Also, the reconstruction of crane equipment at Unisteel permitted an increase in the final coil weight from 10 tonnes to 15 tonnes. The plant produced 6,000 tonnes of such rolled material last year. The increased coil weight gives downstream processing the opportunity to save time and costs on trimming in coil handling, to have more efficient cutting during the production of profiles and saves on butt-welding operations.

Meanwhile, Ilyich Steel began to produce a new class of zinc coating: Z100. The plant developed the technology for the production of high quality coating. This is the minimum class of zinc coating, according to the EN10346 standard, intended for construction applications. The rolled material is used for the manufacture of items operated in a dry climate or indoors. Last year, 23,500 tonnes of the new product were supplied to the market.

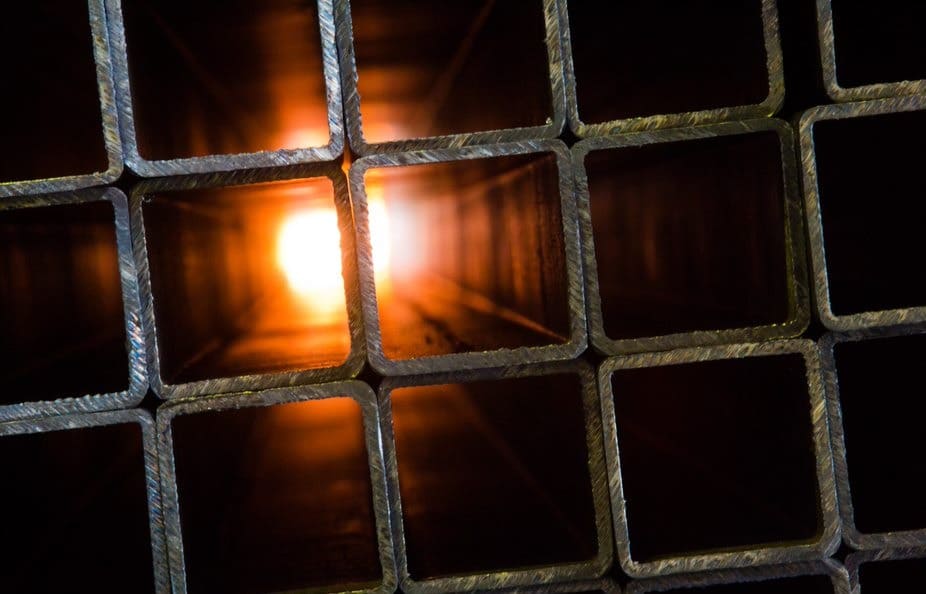

Electric welded tubes

In 2020, Metinvest started to produce tubes with special requirements for negative thickness tolerances. The reduction of tolerances helps to avoid wall over-thickness and increase the overall tube length by up to 10% during the downstream processing. Square and rectangular hollow sections are used for the manufacture of steel structures for different applications, as well as in the heavy machinery and furniture industries and various infrastructure projects. During the year, Metinvest enterprises sold 22,000 tonnes of such products.