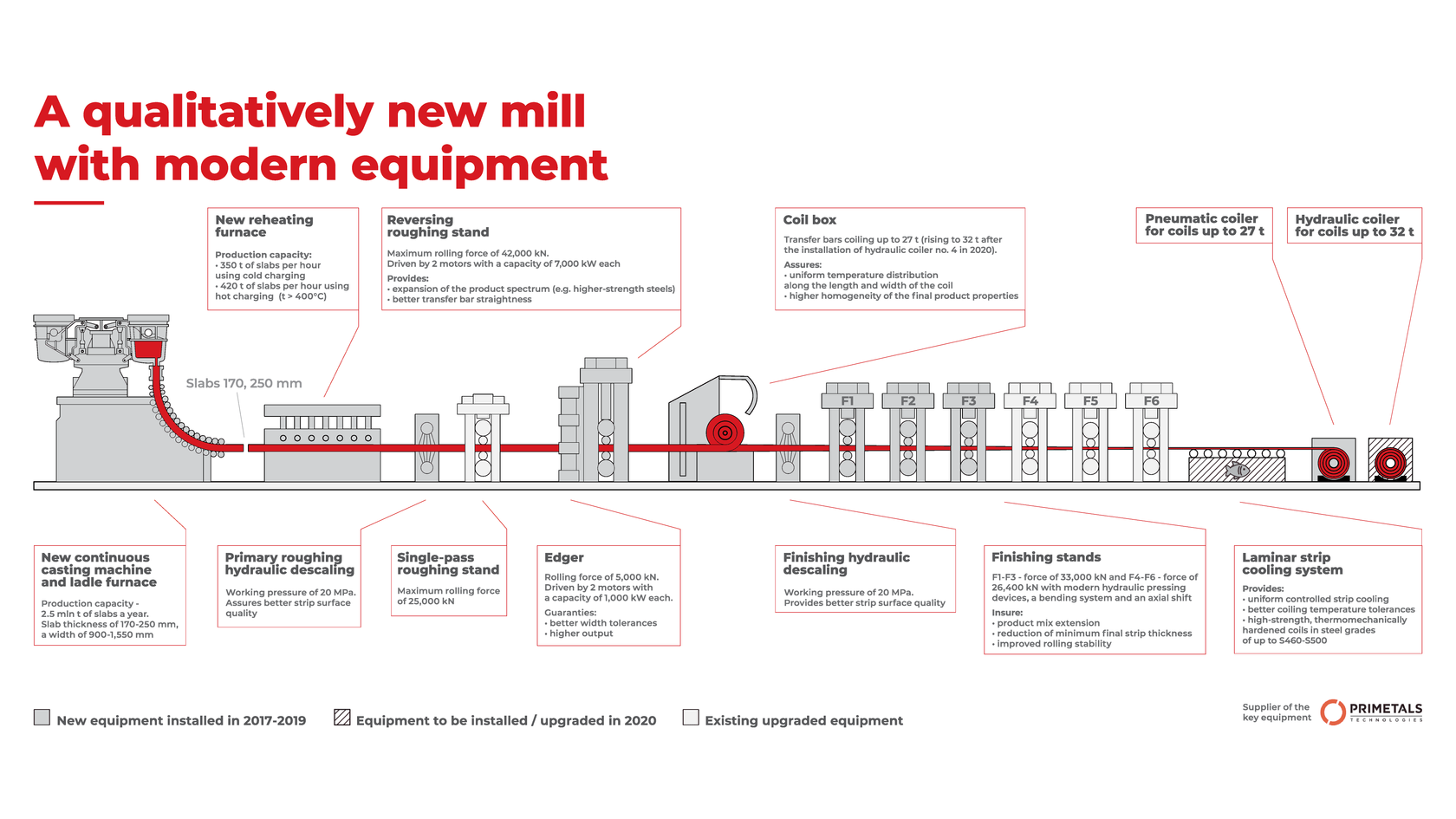

The revamp of the 1700 HSM began in 2018. The first phase included the commissioning of a reheat furnace and the installation of a heavy coiler. This made it possible to increase coil weight to 16.5 tonnes (compared with 9.5 tonnes before the revamp).

During the second phase, two new descalers, a roughing mill stand, a coilbox and other process equipment are installed, and the 1700 finishing mill is reinforced and modernised.

Of the five old roughing mill stands, one remains, while the others are replaced with a more powerful reversing mill stand equipped with an edger for vertical slab reduction. The new mill stand has an automated control system to ensure stable production of quality feedstock for the finishing mill.

The coilbox is installed after the roughing mill to provide for intermediate coiling of long workpieces during the rolling of heavy coils. This helps to equalise the temperature along the entire length of the workpiece, which contributes to uniform strip reduction during the rolling in the finishing mill, creates more accurate tolerances, and improves the stability of mechanical properties and the microstructure of the finished product.

The revamp is going to be finished in fall 2019, after that the equipment tests will start.

There are the five main special features of the renewed 1700 HSM here below.

1. Heavier coils

Compared with what it produced before the revamp, the renewed 1700 HSM can increase coil weight by almost 3.5 times to 27 tonnes with a potential further increase to 32 tonnes. Coils are made from premium slabs produced by the new continuous casting machine that was put into operation in 2019.

Hot rolled coil is in demand in the construction, machine building, pipe making and metal processing industries.

Heavy coils help to save time and processing costs, because the heavier the coils, the less intermediate operations will have to be done by the end user.

2. Thinner coils

The minimum thickness of rolled steel produced to European standards is going to be reduced from 1.8 mm to 1.2 mm, while the output of such thin-gauge material will increase. This saves customers of these products time and resources, because thin hot-rolled steel is an effective substitute for cold-rolled material in many applications and, therefore, does not require additional rolling. This product will also be available as part of package sales, when the maximum possible variety of sizes can be purchased from one supplier.

The ability to produce thinner hot-rolled material is especially important for shaped pipe manufacturers and customers in external markets, which use this material for further cold rolling.

3. Wider product range

Production of thin-gauge material on the 1700 HSM opens new opportunities to extend the range of cold-rolled products, as well as to increase the output of galvanised steel sheets and coils.

Ilyich Steel is already producing some new products, including hot-rolled pickled seamless coils with a weight of up to 15 tonnes and cold-rolled seamless coils with a weight of 14.0-14.5 tonnes.

4. Improved surface quality

Following the revamp of the hot strip mill, the quality of coils will meet the most stringent global standards. The 1700 HSM’s Austrian equipment will provide for stable process modes, assuring low size tolerance and homogeneous structure, as well as balanced distribution of properties along the length and width of the rolled stock.

5. Output increase

Presently, the 1700 HSM can produce some 1.3 million tonnes of hot-rolled material per year. Ilyich Steel plans to increase its annual output to around 2.5 million tonnes by 2020, of which 1.5 million tonnes of high quality hot-rolled coils will be freely available on the market. All products are certified to European standards and sold primarily on export markets.