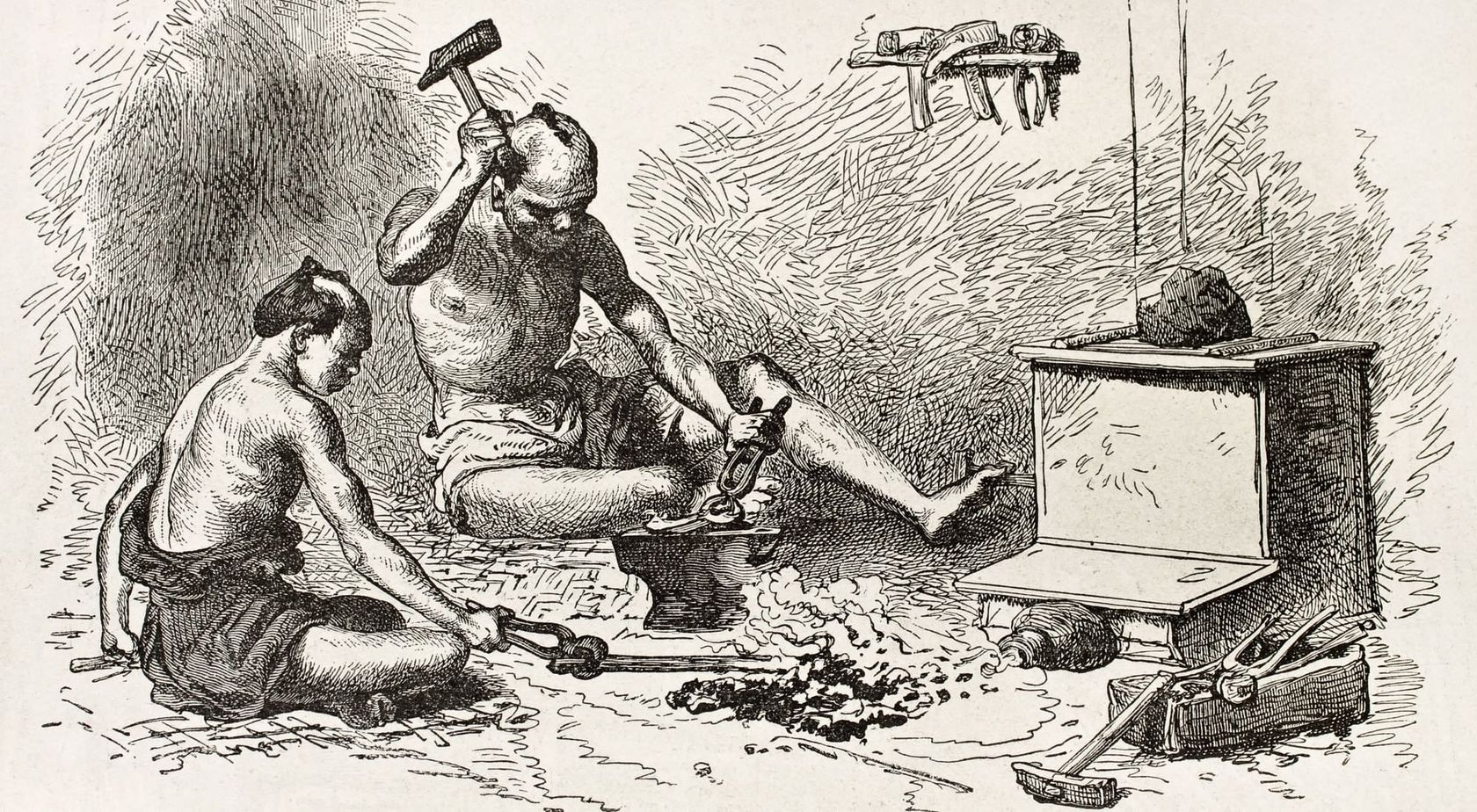

In Japan’s Sanjo, the past meets the present. Here, traditional steel-crafting techniques combine with modern technology to create some of the world’s sharpest blades. Two hours away from Tokyo via bullet train, Sanjo has been a centre of blacksmithing in Japan since the feudal Edo Period.

Secrets of excellence

Local craftsmen have every reason to be proud of their heritage. The intricately carved blades produced here are prized for their strength and durability. These steel knives are used by top chefs around the world in the foremost sushi restaurants and even as the cutlery at the annual Nobel Prize ceremony dinner.

The secret to success and reputation of Sanjo’s craftsmen lies in the pursuit of perfection in even the smallest of details. Dr Koshi Yamamura is the third-generation President of Yamamura Manufacturing, founded by his grandfather in 1948. “Our blacksmiths don’t just shape objects out of steel, we consider the very microstructure of the steel to create our blades,” he says. “We forge steel using the lowest possible temperature to maximise the strength and durability of our products.”

The efficacy of local blacksmiths’ work is dependent on the specific type and quality of steel used. Most of the products for this application require the steel’s carbon content to be 1%. “Different metals, including the steel for Japanese swords, have different properties and uses. Blacksmiths apply their expertise to bring out the best in their chosen source material,” Yamamura says. Here, they use locally sourced high-carbon steel for Japanese blades that has been specifically formulated to hold a sharp edge. It takes decades of experience for craftsmen to bring the best qualities out of the metal.

Tokifusa Iizuka has been making knives in Sanjo for 50 years. His Shigefusa Knives brand is a local legend. In 2007, Iizuka received an award from the governor of Niigata Prefecture, declaring him to be a master craftsman.

Shigefusa knives are highly prized by chefs around the world for their durability and razor-sharp edges. Each knife is hand-forged by the master Iizuka and his two sons. A single knife can take an entire day’s work from start to finish. The craftsman has a long waiting list. Some customers wait more than three years for their handmade knife to be completed.

“If I told my sons how to make this or that knife, they might be able to do an adequate job, but they would never be able to become masters in their own right,” says Iizuka. Hard work, trial and error, he says, are necessary parts of the path to becoming a real master.

“When I first started, I would fight with the steel and try to make it obey me,” he says. “But as I have grown older, I have built a friendship with the steel.”

Traditionally made Japanese knives, if maintained properly with regular sharpening, last decades. This is possible because they are made of steel, which is soft enough to sharpen, yet hard enough to endure decades of professional use.

“The quality of the steel must match the quality of the sharpening stone through a very finely struck balance,” says Dr Yamamura. “Then the knife can last 10 years, 20 years, or can even be passed down to the next generation. Warriors in feudal Japan would call their sword tamashii, which means soul. Our ancestors used the same techniques and the same materials as we do now, so today’s steel blades also contain the soul of the samurai.”

Modern sushi knives in Japan

Nowadays, Japan’s famous sushi chefs use knives made of traditional Japanese steel like Iizuka’s to prepare finely cut fish. Sushi chef Katsunori Ikeda runs Sushi Katzu in central Tokyo, near the Hanzomon Gate of the Imperial Palace.

“The relationship between a chef and his knife is a deeply personal one,” says Ikeda. “Mine has been with me for 40 years.”

Sushi chefs traditionally use three knives: yanagiba, deba and usuba. The long, slender yanagiba culinary knife is used to slice the fish that will become sushi and sashimi. The large and heavy deba knife is used to fillet whole fish, and the usuba knife is used to prepare vegetables.

However, Ikeda is quick to mention that a good yanagiba can be used to accomplish all of the necessary tasks. “With a single, well-made Japanese yanagiba steel knife, I can fillet an entire 100-kilogramme maguro tuna fish from start to finish,” says Ikeda.

Japanese sushi chefs use traditionally forged steel knives because their blades are sharp enough to slice through flesh in a single motion.

“I was born the son of a sushi chef but I also always had a fascination with science,” says Ikeda. “There are scientific reasons why an exquisitely sharp Japanese blade makes a difference in preparing delicious sushi. A swift cut made in a single motion ensures that the delicate cell structure of the fish itself is kept intact, so that the enzymes necessary to the fish’s distinctive taste and texture come out. Some people may think that sushi chefs need many knives to do their job, but I only use two, one of which is a 33-centimetre long, durable yanagiba knife.”

The future of Japanese knives

Traditional crafting techniques passed down by generations of masters like Iizuka are the foundation of Sanjo’s craftsmanship. But as Japan’s population shrinks, there is rising concern as to whom and how to pass on the knowledge and experience of ancestors. This is one of the reasons why Dr Yamamura obtained his doctorate in engineering, making this renowned craftsman also a scholar.

“While our craftsmen have mastered traditional steel crafting techniques, they are not necessarily able to explain the scientific basis behind the craft,” he says. “I can fix this and become the very link that connects our community of craftsmen to the world.”

But what really keeps craftsmen like Yamamura focused on steel? According to the master, it is fascinating to work with this material.

“Blacksmithing lets you do all the things your parents told you not to do when you were a kid, like working with fire and touching sharp objects,” says the master with a smile on his face. “As you shape steel into a blade, you can see it change before your eyes. This is something mesmerising that I would like everyone to see for themselves.”