What is a robot? The word ‘robot’ was first used almost 100 years ago in 1921 by Czech writer Karel Čapek in his play, R.U.R. However, even today, there is no clear definition of this technology. Anything that is a functional extension of a person can be considered a robot. That said, ’anything’ made of steel, plastic or other materials has evolved significantly over the last few decades: from external mechanical control to self-learning and self-development using artificial intelligence.

The International Federation of Robotics (IFR) defines a robot as a working mechanism that can be programmed along several axes with a certain degree of autonomy and capable of moving within a certain environment to fulfil its tasks. The IFR divides the robotics into two large groups:

- Industrial (to perform industrial automation-related tasks)

- Service (to perform useful tasks for humans and equipment)

Robots and Industry

According to the IFR, the overall number of industrial robots operating worldwide increased by 12% to 2.7 million in 2019. However, sales slowed down slightly compared to 2018, to 373,000 units due to a downturn in the automotive and electronics industries.

Over the past five years, the number of industrial robots worldwide has almost doubled. The main users of robots are China and Japan. In addition, the USA, South Korea, and Germany are in the top five of the global rating. India is rapidly catching up to these countries.

The IFR highlights the increasing sales of machines using human-robot collaboration, or ‘cobots’. These are industrial robots that are programmed to collaborate with human beings in the same workplace and which are incapable of even accidentally harming any living being.

It is an interesting fact that increasing demand for robots is accompanied by a decrease in their price. Such factors as the distribution of 3D printing using composite materials and other technologies have made robots more acceptable and improve their quality and contribute to robotics. In the meantime, investments in robotics are growing and are estimated at billions of US dollars.

Who uses artificial helpers in production? The automotive and electronics industries account for two- thirds of the users. The steelmaking and metals industries account for a little more than 10% of the market. Other sectors of the global economy are rather difficult to robotise. Generally, such helpers perform manipulation and housekeeping actions.

The COVID-19 pandemic helped bring about a rethink of the approach to modernising and automating production processes. More and more companies think about implementing both traditional robots and cobots, which work hand-in-hand with humans in a safe manner and are integrated into their jobs.

Robots and Services

Sales of service robots have hit a record high. According to the IFR, this segment increased by 32% to US$11.2 billion in 2019. The IFR thinks that COVID-19 will further strengthen the market. Robotic disinfection solutions and robotic logistics solutions in factories and warehouses or robots for home delivery are examples of this trend.

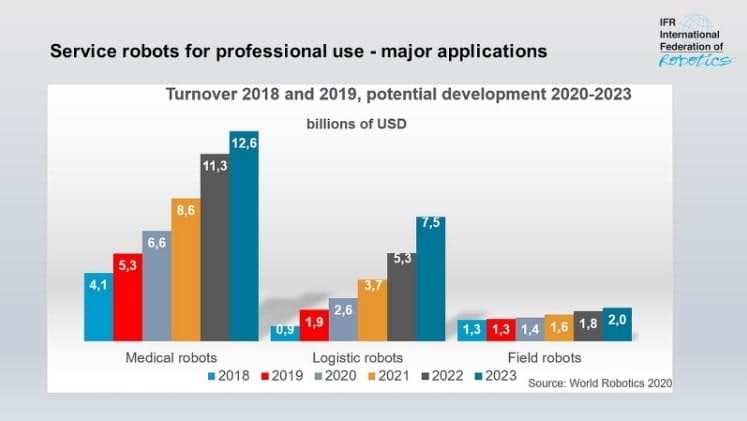

Today, medical robots account for around 50% of the revenue in this segment. Their sales reached US$5.3 billion (+28%). This was driven by demand for expensive robotic surgery systems. It is worth noting that 90% of such robots are from America and Europe. By 2023, this figure is expected to more than double, reaching US$12.6 billion.

At the same time, the market for robotic logistics solutions will almost triple from US$2.6 to US$ 7.5 billion. Such robots were initially used in warehouses, but with technological advancements, they have become an integral part of the smart factory. Assuming 24-hour operation, such investments are repaid within 2‐3 years and often much more quickly. In addition to warehouses and factories, logistics robots are actively used in healthcare in many developed countries.

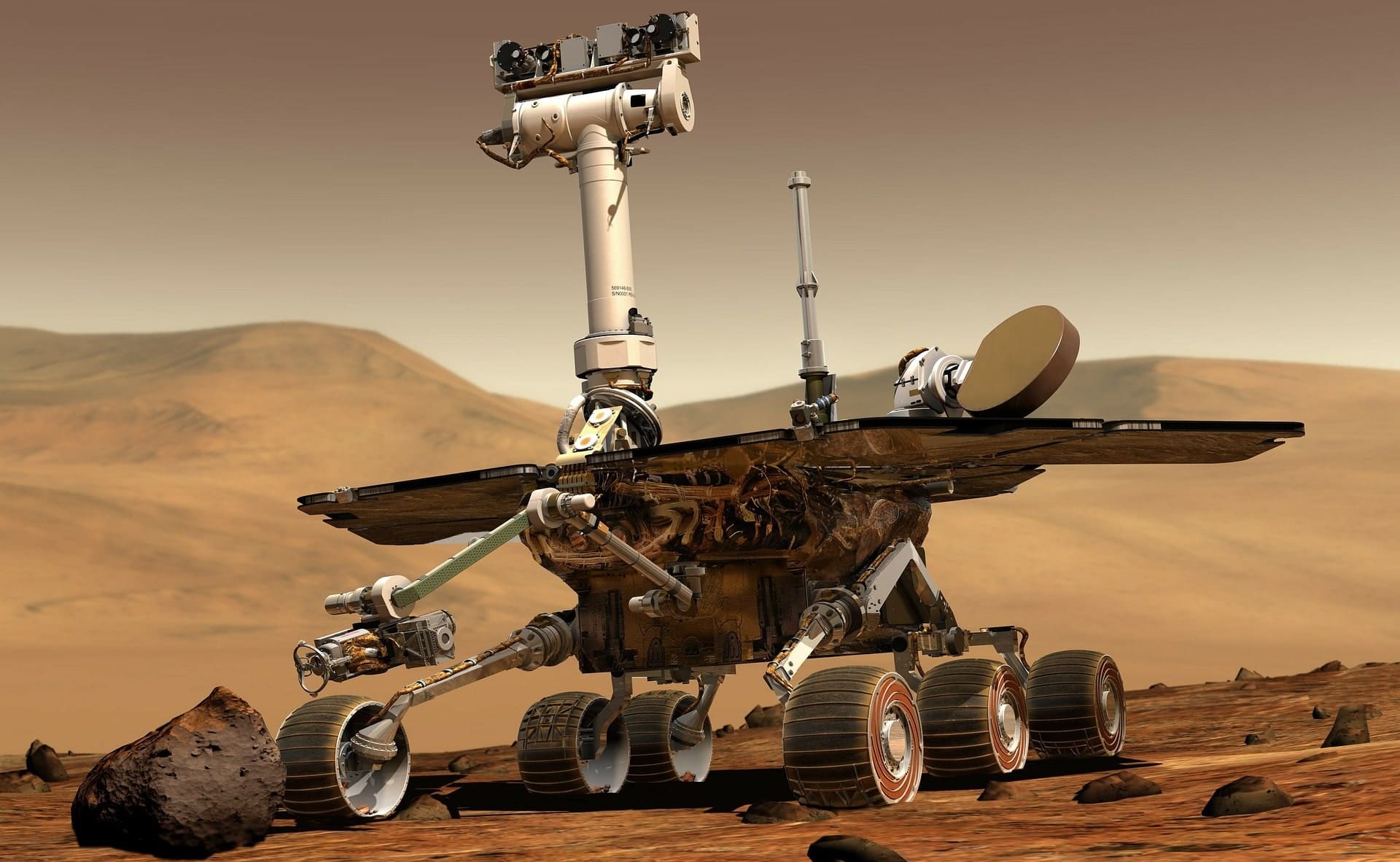

Robotics for agriculture (so-called field robots) is also rapidly developing. Such robots are used not only in the fields but in diary, livestock farming, etc. Although this segment increased by only 3% to US$1.3 billion in 2019, it is expected to surge in the near future due travel restrictions between countries. In particular, this impacts seasonal workers who travel from Eastern Europe to Western Europe for harvest season. A shortage of labour supply may lead to the replacement of human workers with robots.

The market of domestic robots is also booming. They include vacuuming and floor cleaning robots, lawn-mowing robots, entertainment robots, etc. In 2019, more than 23.2 million units (+34%) were sold for a total value of US$5.7 billion (+20%). By 2023, sales of domestic robots will double, reaching US$ 10 billion. However, the demand for entertainment robots will grow not as rapidly, only by 50% to US$ 1.9 billion.

In Ukraine, robot vacuums are rather common; however, assistance robots for elderly or handicapped people (exoskeletons in particular), a fast growing market, are still very rare. However, they are sold for value of almost US$100 million annually in the rest of the world.

China is an absolute leader in using robots. Meanwhile, most of the largest world's manufacturers are located in another Asian country, Japan. They include FANUC, Yaskawa, Kawasaki, Nachi, Denso, Mitsubishi, Epson, etc. Other well-known specialists in robotics include KUKA (Germany/China), ABB (Sweden/Switzerland), Omron (USA), Staubli (Switzerland), Comau (Italy), and Universal Robots (Denmark).

At the same time, the production sites of many Japanese, European, and American companies are located in China, which developed an ambitious robotics development program.

Steel for Robots

What steel is used for robot manufacturing? Modern robotics is not an enemy to humans in the form of androids but rather machines to help people and companies. They can carry heavy loads an average person cannot carry or replace human workers to perform work that requires stamina, round-the-clock performance or resistance to challenging environments.

Therefore, mechanical limbs and other parts of robots are made from composite materials where metal and alloys, steel in particular, play an important role.

The combination of these materials depends on the application of the robots. When it comes to industrial robotics, aluminium, iron and carbon steel are used to make body parts. Engineering steel of various grades is used for drive systems. It usually includes structural alloy or high alloy rolled steel, including stainless steel.

As mentioned above, robots should perform actions utilising several axes. Therefore, robots are designed to have a large number of joints and drives with bearings, gears, and other parts to create movable robots and components. Special and stainless robotics steel is used for such assemblies, in particular ball-and-bearing steel grades (they are designated as "ШХ" (ShKh) in the CIS standards). For a robot to replace a human worker to perform tasks at high temperatures, high alloy steels and nickel alloys are used.

The future shown in Hollywood movies where armies of robots combat armies of people has not yet come. The impact of robotics on industries and our homes is getting stronger.

Nevertheless, experiments carried out by some robot manufacturers that can imitate human motions and learn in the course of carrying out tasks are already showing impressive results and force us to think about finding the right direction for this evolution.