The detractors of the inventor and entrepreneur who has repeatedly not only generated, but also embodied the wildest design ideas, derided it as a children’s drawing, a simplified 3D model from a PlayStation game or the result of Musk possibly having fired everyone who was not afraid to object to him. He took a great risk. But will his idea work?

Commercial success of Cybertruck

An indirect answer to this question can be found in the number of pre-orders for this new electric vehicle that Tesla Motors has received since November 2019 (serial production of Cybertruck will begin only in a year). In just the first couple of days that everyone had the opportunity to pre-order a Cybertruck, the manufacturer’s website received almost 150,000 applications. A week later, Tesla reported that the number of customers had reached 200,000. Fans of Musk and Cybertruck made further calculations: according to them, the website receives almost 6,000 daily pre-orders for the pickup truck. By early 2020, the number of potential buyers exceeded half a million. To confirm their intent to buy the new product, each of them made a $100 deposit with Tesla Motors.

The truth is that this is a drop in the ocean of the declared value of the futuristic vehicle. Cybertruck’s base model costs almost US$40,000. But the most interesting thing is that only 17% of customers have selected it. The rest have preferred more expensive models (the Cybertruck model range’s prices max out at US$70,000). The price difference depends on numerous factors. For example, the number of engines: the more expensive Cybertruck models have two or three motors. In addition, the range that the vehicle can be driven before needing to be recharged varies from 400 km to 800 km. It should also be noted that other electric vehicle manufacturers have so far been unable to surpass the lithium-ion battery performance that Tesla Motors has achieved.

What is Cybertruck made of?

Tesla pays special attention to the materials that it uses for its vehicles. After all, the manufacturer claims that they offer the highest levels of passenger safety. So, the body of Cybertruck is made of super-hard cold-rolled stainless steel, which the manufacturer designates with the code “30X”. The same steel Musk uses for the super-heavy Starship launch vehicle that his company SpaceX is building. SpaceX estimates that the round-trip Mars journey will take Starship about a year, with unmanned crew tests expected to begin in 2022. The unique stainless steel appears capable of withstanding these flights.

In July 2020, Tesla Motors started talking about the possible use of 304L cold rolled stainless steel. Tesla Motors promises that Cybertruck’s body will be strong enough to easily withstand not only heavy metallic objects, but also gunfire from nine-millimetre weapons.

Apparently, the steel is the reason behind Tesla’s unusual design of the vehicle, which, again, received a rather ambiguous public reception. At the same time, Musk gives somewhat contradictory explanations on Twitter for Cybertruck’s polarising design. He writes that Cybertruck’s angular design is cinematically inspired and recalls “Bondiana” and “The Spy Who Loved Me”. He also cites Harrison Ford’s legendary dystopian thriller “Blade Runner” (by the way, the latter has been considered a source of inspiration for architects of futuristic cities made of glass and steel in Gulf countries). Ultimately, Musk explains that the true reason why Cybertruck is so, frankly, “planar”, is related to the properties of the 30X steel grade, tweeting that “you can’t stamp ultra-hard 30X steel, because it breaks the stamping press”.

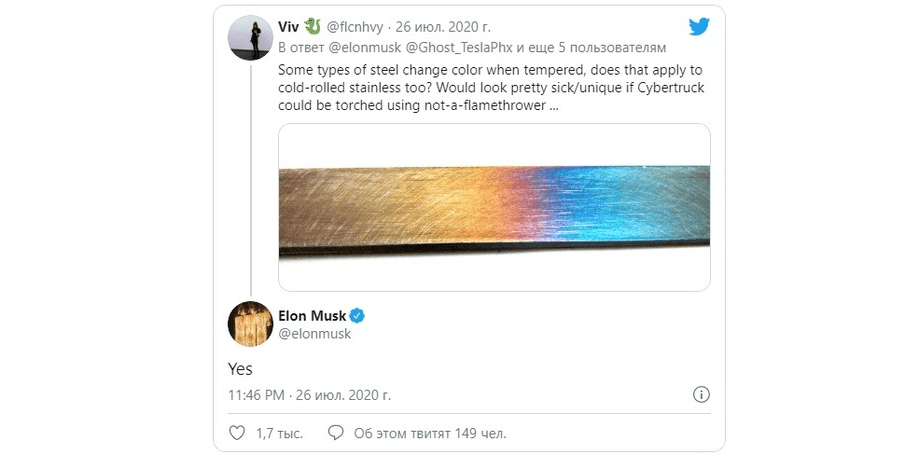

Material characteristics dictate the color range of the Cybertruck. Stainless steel cannot be painted. However, after months of online discussions about the Cybertruck color, one of the fans of the futuristic car suddenly has remembered that some types of steel can change their color shade as a result of heating and become gray, sandy, purple, blue ...

“Yes,” Elon Musk replied, and at that moment the world found out that probably Cybertruck will not be just a metallic color.

How is Cybertruck made?

Cybertruck’s body is made as a single part in one stamping using ultra-strong stainless steel with a thickness of 3 mm. At the same time, Tesla’s designers seem to have been significantly limited by the capabilities of modern stamping technologies, which are unable to achieve a smoother body shape using this material for what Musk calls the “exoskeleton”.

Stainless steel is not a remedy

Instead of the ultra-strong steel used for Tesla vehicles, why not take ordinary stainless steel, an alloy of iron with chrome, and put it into mass production of cars? Plate and sheet machine building steel from carbon and low-alloy steel grades, including high-strength types, are the most popular materials for the production of cars, other passenger and freight vehicles, agricultural and other types of machinery, etc. But even the best samples of such rolled products, despite the most modern anti-corrosion treatment, sooner or later rust, disappointing their once happy owners.

The first and probably the most important reason that no other stainless-steel cars are currently being offered for sale is their potential price. Stainless steel is much more expensive than ordinary grades: its use can sometimes double the cost of the final product. Stainless steel is also more difficult to process and weld than ordinary steel. In addition, cars from stainless steel are not only very heavy, but also during operation, they quickly become covered with a mesh of various scratches. And such steel is difficult to paint.

The paradox, but also the main advantage of stainless steel – its extreme resistance to corrosion – eventually turns into a significant marketing disadvantage. Consumers do not seem to want everlasting cars. They want new, fashionable, innovative cars, not cars that will still look great after having changed several generations of owners. There is also the inconvenient truth that such a “long-running” stainless-steel car could also be unprofitable for the automotive industry, which wants production lines to keep working, not stand idle.

Therefore, both rally legends and solid family coupes are all made using ordinary steel of various strengths, which account for about four-fifths of the car’s weight, including the doors, roof, chassis, exhaust and mufflers. According to the Association of Global Automakers, an average of 900 kg of steel is used in the manufacture of a car. Experts have calculated that, as a rule, these nine hundred kilos of metal are distributed as follows. The biggest portion – about 34% of the total steel – goes to the body and its parts (trunk, doors, etc.). For the vehicle’s body, the metal’s high strength and ability to absorb the inevitable kinetic energy of a traffic accident are critical. Another 23% of the steel is used in the transmission. The suspension accounts for 12% and is, as a rule, high-strength steel. The remainder is made up of the steering parts, brakes, fuel tank, wheels, etc.

The motor vehicle association Ukravtoprom recently reported that more than 67 million cars were produced in the world last year. China was the leader, accounting for about a third of global vehicle production. Based on the data on the average use of steel in the production of one car, it is easy to calculate that in 2019, approximately 60.3 million tonnes of steel were used by the global automotive industry. In his time, Henry Ford took a risk, offering the world the first inexpensive and reliable car. But, as we see, his idea worked perfectly.

That said, what about our amazing contemporary, the innovator and car manufacturer Elon Musk? Will his Cybertruck be a purely niche product or will he be able to significantly expand the current target audience of Tesla car fans?

It is worth remembering that Musk founded his first company less than a quarter of a century ago: together with his brother, he sold software that provided newspaper content. And in 2020, the businessman placed 31st in Forbes’ global ranking of billionaires with an estimated net worth of US$24.6 billion. At a recent Cybertruck presentation, the entrepreneur arranged an eloquent performance: a tug of war between his futuristic Tesla vehicle and the Ford F-150, the most popular pickup truck in the US. This Ford model costs more than US$46,000, which is comparable to Cybertruck’s base price. Musk’s pickup won the competition. But only time will tell whether Cybertruck will grab market share from America’s favourite pickup truck. As Musk says about his audacious projects, “When something is important enough, you do it even if the odds are not in your favour”.