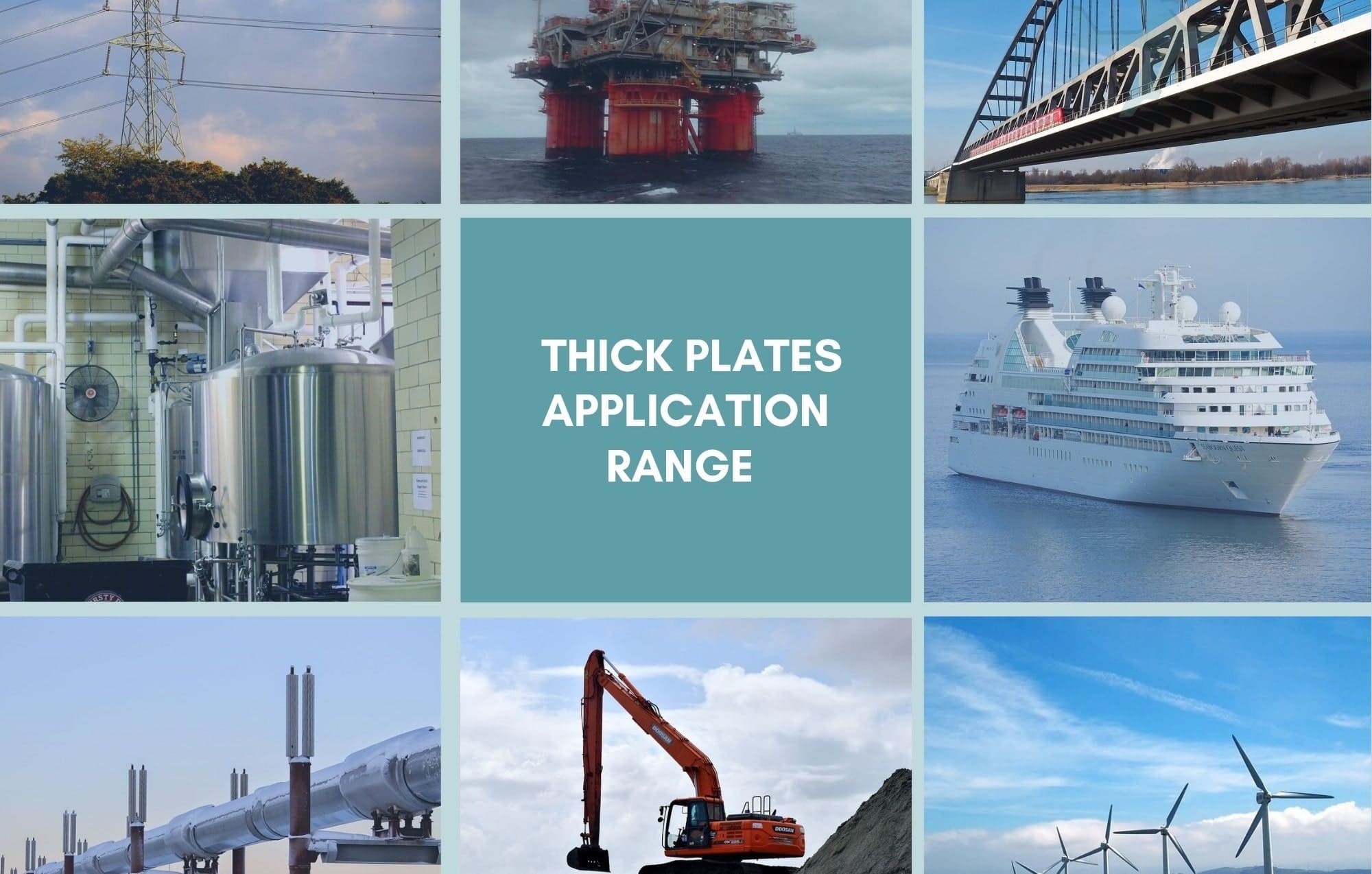

While one system of standards states that thick plates include flat steel (plates and coils) with a thickness of 4 millimetres or more, another system of standards allows for a thickness of 3 millimetres or more. However, various analytical agencies assume different minimum limits for thickness: 5 millimetres, 6.5 millimetres and even as much as 10 millimetres. Regardless, it is impossible to imagine most industries without thick plates, especially shipbuilding, construction, machine engineering, as well as the manufacture of large diameter pipes and boiler equipment.

Structural plates account for more than one-third of total consumption and are in the highest demand in the segment of thick plates. Shipbuilding plates account for one-fourth of consumption and are in second place, while high-strength plates have a share of around 20% and come in third.

Global market

The international publication CRU estimates global production capacity for thick plates at approximately 226 million tonnes a year, whereas consumption amounted to around 150 million tonnes in XXXX. More than 75% of thick plates are consumed in Asia – including Singapore, China, South Korea and Japan – which has become the centre of global shipbuilding in the last few decades, in addition to actively developing infrastructure projects. Elsewhere, thick plates are in high demand in Europe, North America and the CIS.

Such industries as shipbuilding, construction and machine engineering consume most thick plates. Each of the above segments sets its own requirements for steel plates, which can be unique. Some steels can be certified according to two standards at a time: shipbuilding and construction. For example, structural steel S355J2 can be made and rolled so that its chemical composition and mechanical properties fully correspond to shipbuilding steel grade А32. However, there are steel grades that differ in their chemical composition, physical and mechanical properties, and delivery condition. For example, good weldability of thick plates is crucial for the construction sector, while abrasion resistance is needed for some applications in the engineering industry.

Metinvest Group accounts for around 2.4% of global production of thick plates. Most of its plates are sold to geographic Europe, where five of the Group’s plants operate. In Ukraine, Azovstal and Ilyich Steel have a total production capacity of more than 4.3 million tonnes of thick plates. In Italy, Ferriera Valsider and Metinvest Trametal have a total production capacity of around 1 million tonnes. In the UK, Spartan has annual production capacity of 200,000 tonnes of thick plates. These plants produce rolled steel using concast slabs supplied by Ilyich Steel and Azovstal. Overall, Metinvest makes 5.5 million tonnes of thick plates in Europe, making the Group the largest producer in the region.

Production process

Thick plates are produced at reversing hot-rolling mills or by cutting hot-rolled coils of appropriate thickness to length. Hot rolling is the most common process used to produce thick plates. It ensures the optimal combination of geometric accuracy, mechanical properties and surface quality. That said, there is no need to use a more expensive additional process stage, such as cold rolling.

Slabs are used to produce steel plates, which are heated in a reheat furnace, rolled at a hot-rolling mill, cooled and cut to length.

The next step is heat treatment (this is optional, as required by the standard or the customer), where the plate is reheated in a furnace and cooled in certain modes. In an alternative method, process parameters are set during rolling to achieve properties that are identical to those achieved by reheating separately in a furnace. Nowadays, for example, normalising rolling has replaced normalising in furnaces for most industrial applications. This process is much more cost effective, while the resulting structure and properties of the rolled steel fully correspond to those achieved by normalising in a furnace.

Heat treatment can also be carried out at the end user’s site. For example, rolled products made of boron steel are delivered hot rolled to agricultural machinery manufacturers. For harrow manufacturing, machine builders first cut out the required part from the plate, drill a hole in it, reheat that part in a furnace, shape it and cool it with water. By doing so, the part obtains another set of properties, becoming stronger and more wear resistant.

Additional options that can be offered by plate producers include levelling and shot blasting. The first operation implies the levelling of plates using specialised machines or presses to improve flatness. Shot blasting cleans scale, rust or small defects from the metal’s surface using steel shot. The shot blasted plate is then coated with a protective primer to prevent corrosion. Metinvest Group carries out shot blasting and painting at its Ferriera Valsider plant in Italy.

Some plants and service metal centres offer such services as cutting, bending and preparing parts for further manufacture. They are not metallurgical processes but machining that reduces the number of operations to be carried out by the end user. For example, such services provide the buyer a door slab or pre-cut panel to finish at its production site.

Specifications

All thick plates must meet the following key requirements:

- dimensions must comply with the order and delivery terms, as well as the tolerances specified in standards and technical specifications

- plates must be evenly trimmed on all sides or have a milled edge; in all cases, plates must be rectangular

- plate surfaces must be even and smooth

- deviations in plate flatness must not exceed those permitted by standards and technical specifications

- plates must be stamped, marked and packed in accordance with the requirements set forth in standards and regulations

Plates are primarily delivered based on their theoretical weight. Each lot of products must be supported with a quality certificate and a certificate of compliance with the standards or technical specifications outlined in the order, which contain all characteristics of the steel product.